Material handling has evolved over the years to the extent that we have different types of equipment for different tasks- both simple and sophisticated. In some cases, the cart is always the best option for some of the simple tasks.

The key that should guide your acquisition of any material handling equipment should be in three areas:

- Efficiency

- Cost

- Safety

Customization

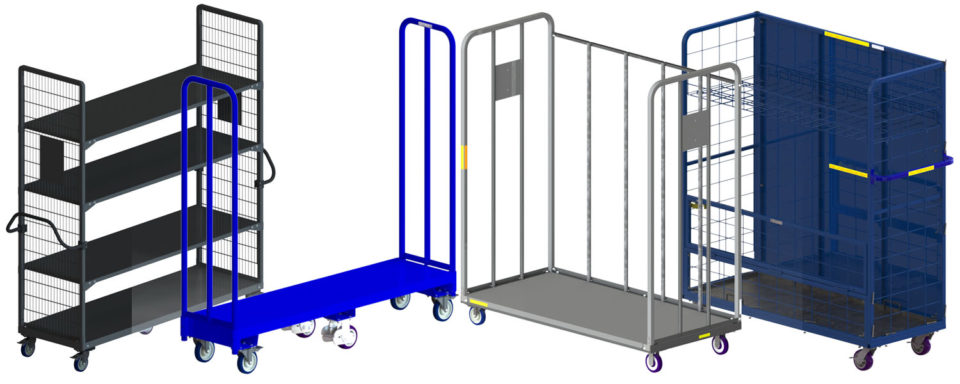

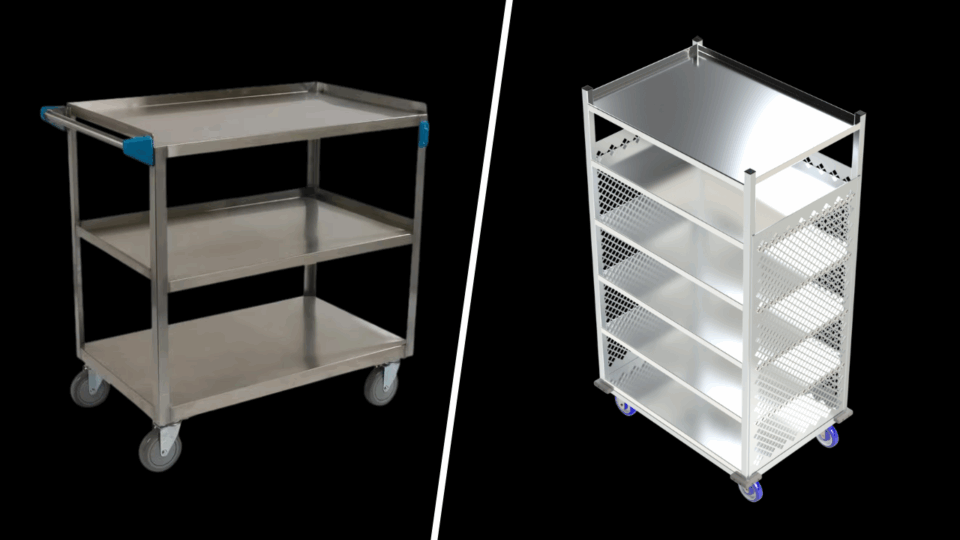

Not all warehouses are built the same and some tasks require a unique set of equipment. Achieving these tasks using sophisticated material handling equipment is not efficient since they provide minimal customization flexibility. This is where the simple cart wins, especially when you find a manufacturer, like National Cart Company, that is willing to design a cart to meet your needs and standards.

Cost Minimization

One expense of your business is the cost associated with material handling equipment. If you go for the cart that has a simpler design with a few move-able parts your maintenance costs will be reduced by a great margin. Carts are cheaper when compared to other material handling equipment like forklifts which have a very steep cost of acquisition due to their sophistication.

The ability to customize your cart gives it a more ergonomic functionality that can fit a specific task. Normally this enables your workers to obtain maximum comfort during even the most demanding tasks. Allowing them to perform their tasks much faster and efficiently, which is great for productivity.

Improved Safety

The simplicity of material handling equipment is a major contributor to the safety standards in a warehouse. If your day-to-day tasks can be done much more efficiently with a cart, then go for that option.

A major reason for that is that you will see to it that the common accidents due to forklifts are eliminated. OSHA estimates forklift fatalities account for 85 fatal accidents per year; 34,900 accidents result in serious injury; and 61,800 are classified as non-serious.

Fatal Accident Type% Where fatalities occur%

Crushed by vehicle tipping over 42% Mining 1.2

Crushed between vehicle and a surface 25% Construction 23.8

Crushed between two vehicles 11% Manufacturing 42.5

Struck or run over by a forklift 10% Transportation 11.0

Struck by falling material 8% Wholesale trades 12.5

Fall from platform on the forks 4% Retail trade 9.0

Material handling carts provide a safe environment for your workers, which also means less downtime and therefore improved productivity. You should carefully audit the needs of your warehouse and ensure you go for much simpler equipment like carts if it is suitable for the job than the more sophisticated options. Carts will give you the opportunity to customize them to fit the demands of the nature of your material handling tasks. They are cheaper to operate, which is good for the bottom line, and they are also much safer to use compared to forklift