If your business uses material handling equipment, it’s important that you know how to keep up with the evolving industry to stay ahead. With new technologies, rising customer expectations, and an increasing focus on supply chain efficiency, the landscape is rapidly evolving. As we enter 2025, here are the top trends shaping the future of the material handling industry.

1. Automation and Robotics Integration

Automation is a rising trend in the material handling industry, with robotics leading the way. More and more businesses are using technology to save time, reduce manual work, and improve accuracy. In 2025, we will likely see more companies adopting collaborative robots that work alongside people to increase productivity. These robots help businesses cut costs and move products faster, making their operations more efficient and adaptable.

2. Sustainability in Material Handling

Sustainability is now a must for the material handling industry. In 2025, companies will be focusing on eco-friendly practices more than ever, like using electric forklifts, recyclable materials, and energy-efficient warehouse designs. Many are also adopting circular economy strategies—refurbishing and reusing equipment—to reduce waste and cut down on their carbon footprints.

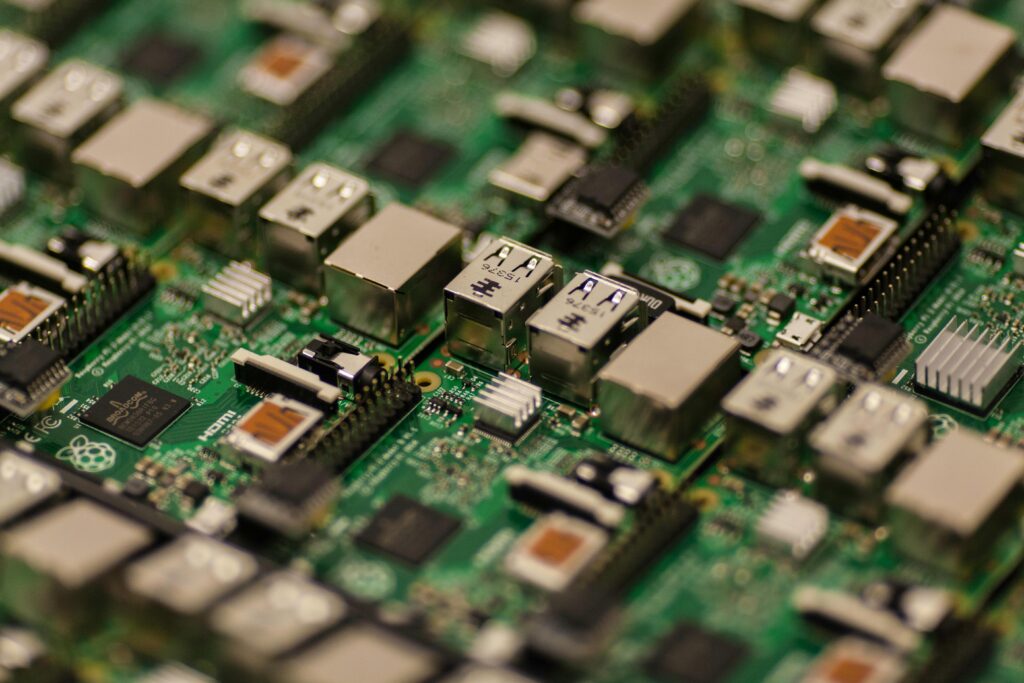

3. IoT and Data-Driven Insights

The Internet of Things (IoT) is changing how businesses monitor and maintain material handling equipment. IoT devices give real-time updates on equipment performance, helping companies fix issues before they cause downtime.

For example, sensors on carts and forklifts can track usage to keep them running smoothly and last longer. In 2025, more businesses will use IoT to make smarter decisions and run operations more efficiently.

4. E-Commerce Drives Innovation

With customers demanding faster shipping, businesses are turning to innovative solutions to meet these e-commerce expectations. Micro-fulfillment centers and advanced order-picking systems are gaining popularity, enabling businesses to process orders more quickly and efficiently. Tools such as tote pick carts and order-picking carts have become essential for managing the high demands of e-commerce operations.

5. Focus on Worker Safety and Ergonomics

In 2025, businesses will be focusing more on worker safety and comfort. Material handling equipment now includes features like adjustable-height carts and lightweight materials to reduce strain on employees. These improvements not only help keep workers safe but also boost productivity by cutting down on injuries and downtime.

6. Customization and Modular Design

Every industry has unique needs, which drives the growing demand for customizable and modular equipment. Modular carts and racks allow businesses to adapt their equipment to specific tasks, providing the flexibility needed as operations evolve. In 2025, companies like National Cart lead the way as they offer tailored solutions that enhance efficiency across various industries.

7. AI-Powered Warehouse Management

Artificial intelligence (AI) is revolutionizing warehouse management systems (WMS). AI helps predict demand, manage inventory, and spot workflow issues in real time. It also improves how material handling equipment operates, making warehouse processes smoother and more efficient, no matter the size of the facility.

Staying Ahead in 2025

For businesses that rely on material handling equipment, keeping pace with these trends is essential for success. Whether it’s investing in automation, embracing sustainability, or leveraging IoT and AI technologies, staying informed and proactive ensures operational excellence in a competitive market.

At National Cart, we’re dedicated to providing innovative, high-quality material handling solutions that meet the needs of modern businesses. Contact us today to learn how our equipment can help you stay ahead in the material handling industry this year and beyond!